Digital Transformation in Industry 4.0

Digital Transformation in Industry 4.0

Introduction

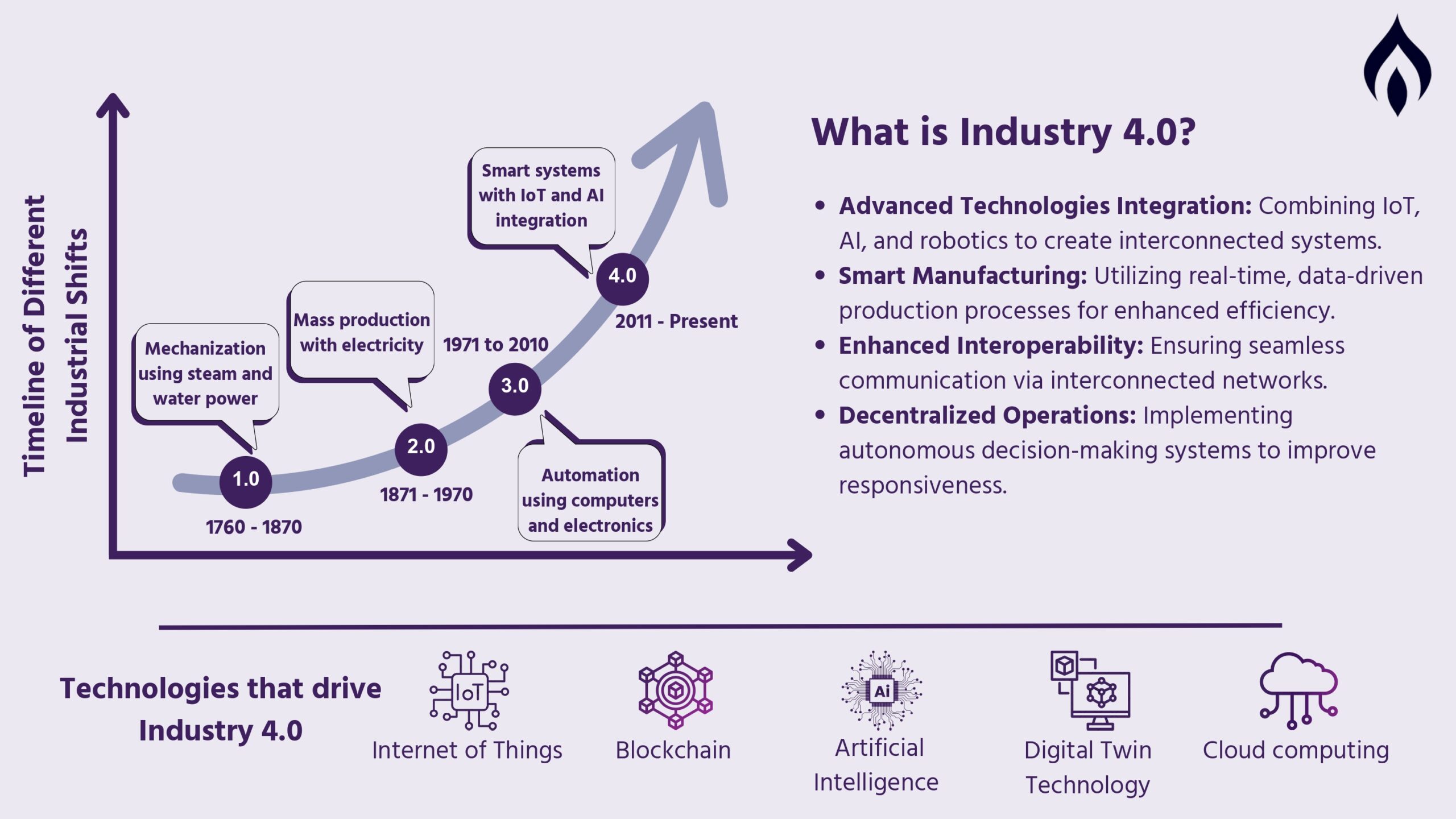

What if you walk into a factory and see machines talking to each other, taking real time decisions and every other work that a human worker does in a factory. That’s called Industry 4.0 – a revolution powered by digital transformation, where each task is performed completely by machines and seems almost alive. It’s not just robots, its about business adopting to the latest technology that makes the work smarter, faster, and more efficient. This article provides a comprehensive roadmap on how digital transformation is shaping the industry and making companies more efficient.

- The Building Blocks of Industry 4.0

1.1 Internet of Things (IoT)

Think of IoT as the magic glue connecting machines, sensors, and devices. In a smart factory, devices share real-time data—helping to spot issues before they become problems and making maintenance a breeze.

1.2 Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML aren’t just buzzwords. They’re the brains behind predictive maintenance, quality control, and even optimizing production. Imagine having a virtual assistant that analyzes massive data sets and gives you insights to tweak your process on the fly!

1.3 Big Data and Analytics

In the era of Industry 4.0, data is everywhere. Big data analytics takes these enormous data streams and turns them into actionable insights, guiding smarter decisions from the shop floor to the boardroom.

1.4 Cloud Computing

The cloud is like your digital toolbox—always available and ready to store, process, and analyse data without the need for expensive hardware on-site. This flexibility means you can access critical information anytime, anywhere.

1.5 Cyber-Physical Systems (CPS)

CPS brings digital smarts into the physical world. By merging software with hardware, these systems can adapt on the fly—automating production lines and keeping logistics running smoothly.

1.6 Digital Twin Technology

Imagine having a virtual replica of your production line that you can experiment on without risking real-world downtime. That’s the power of digital twins: they let you simulate, test, and optimize before making any changes.

1.7 Blockchain

Blockchain isn’t just for cryptocurrencies. In manufacturing, it helps track products from creation to delivery, ensuring transparency and authenticity—something increasingly valuable in a connected world.

1.8 Robotics and Automation

Smart robots aren’t here to take our jobs; they’re here to handle the repetitive tasks so we can focus on creativity and innovation. Collaborative robots, or “cobots,” work alongside humans, making the workplace safer and more efficient.

1.9 Additive Manufacturing (3D Printing)

3D printing is revolutionizing prototyping and production. Whether you need a one-off custom part or a rapid prototype, 3D printing offers flexibility that traditional manufacturing just can’t match.

- Why Digital Transformation Matters

2.1 Boosting Efficiency and Productivity

By automating repetitive tasks and providing real-time data, digital transformation helps you get more done in less time. Imagine reducing downtime with predictive maintenance and streamlining production processes so well that everything just “flows.”

2.2 Cutting Costs

Think about the money saved when machines predict their own maintenance needs. Not only do you avoid expensive breakdowns, but you also reduce labour costs with smart automation working around the clock.

2.3 Enhancing Quality and Customization

With AI and analytics, quality control gets a major upgrade. Products are more consistent, and thanks to customization options, you can cater to individual customer needs—without sacrificing speed.

2.4 Empowering Better Decisions

Data-driven insights mean you’re no longer guessing. Leaders can make informed decisions, fine-tune operations, and react swiftly to changing market demands. Developing a strategic roadmap based on these insights is like having a GPS for your business strategy.

2.5 Increasing Flexibility and Agility

In a fast-changing world, the ability to pivot quickly is invaluable. Digital transformation makes your operations nimble, allowing you to adapt to new trends, unexpected challenges, or evolving customer preferences with ease.

2.6 Promoting Sustainability

Smart manufacturing isn’t just good for business—it’s good for the planet. By optimizing resource use and reducing waste, these technologies contribute to a greener, more sustainable future.

2.7 Improving the Customer Experience

In today’s market, customers crave personalization. Faster production cycles, high-quality products, and predictive analytics translate into a smoother, more satisfying customer journey.

- The Human Side of Digital Transformation

3.1 Overcoming Implementation Challenges

Transitioning to Industry 4.0 isn’t without hurdles. High upfront costs, cybersecurity risks, and the need for a digitally skilled workforce are real challenges. However, with a well-structured roadmap, proper planning and continuous learning, these obstacles become opportunities for growth.

3.2 Upskilling and Cultural Change

Digital transformation means a shift in mindset as much as technology. Training and upskilling are key—think of it as giving your team the tools to not only survive but thrive in a digital environment. The future is about blending technology with human ingenuity.

3.3 Embracing a Collaborative Future

Ultimately, digital transformation is about collaboration—between humans and machines. It’s not about replacing people; it’s about empowering them to work smarter, more creatively, and with greater freedom to innovate.

- Real-World Stories

4.1 Smart Factories in Action

Take a look at companies like Siemens and General Electric. They’ve built smart factories where AI predicts equipment failures before they happen, ensuring a smoother, more reliable production process. It’s a win-win: less downtime, more happy employees.

4.2 Predictive Maintenance That Saves the Day

Airbus, for example, uses IoT sensors to monitor aircraft components, predicting issues long before they cause problems. Imagine the peace of mind knowing that maintenance is always a step ahead.

4.3 AI-Powered Supply Chains

Retail giants like Amazon and Walmart have turned to AI to optimize their supply chains. With real-time data and analytics, they’re able to predict demand, manage inventory, and deliver products faster than ever.

4.4 Digital Twins Revolutionizing Design

Companies such as BMW and Boeing use digital twins to simulate and perfect designs before moving to production. This means less trial and error—and more innovation, all while saving time and money.

4.5 Blockchain Enhancing Transparency

Blockchain is making waves in supply chain management. IBM’s Food Trust, for instance, helps track food products from farm to table, ensuring transparency and trust in the system.

- Looking Ahead: The Future of Industry 4.0

As technology continues to evolve, the line between digital and physical worlds will blur even further. With advancements like 5G connectivity, quantum computing, and edge computing on the horizon, the pace of change is set to accelerate. And while Industry 5.0—focusing on human-centric automation—is emerging, the goal remains the same: to create systems that work in harmony with human talent and creativity.

Conclusion

Digital transformation in Industry 4.0 isn’t just a technological upgrade—it’s a cultural shift. It’s about empowering people, enhancing efficiency, and building a future where technology and humanity go hand in hand. By embracing these changes and staying adaptable, businesses can not only survive but thrive in this exciting new era.

Remember, at the heart of all this innovation are the people who make it work. Whether you’re a business leader, an employee, or a curious reader, digital transformation is a journey we’re all taking together—one that promises to make our work, our lives, and our world a little bit brighter.

Add a review

Your email address will not be published. Required fields are marked *